- Home

- Wires & Accessories

- G4™ Nickel Titanium

G4™ Nickel Titanium

What is G4™ Nickel Titanium?

G4™ Nickel Titanium Wire is the result of years of research and development by G&H. G4™ NiTi is made possible by the vast experience and expertise that G&H has developed in working and controlling Nickel Titanium. G4™ NiTi is superior due to refinements and advancements by by G&H in several key areas:

- Material Science

The G4™ Nickel Titanium alloy is unique. G4™ has been exclusively formulated to coordinate with G&H manufacturing processes to yield consistent specific force, memory and elasticity values.

- Precision Manufacturing Processes

Nickel Titanium is an alloy which is complex to process and form. Very slight variations in a multitude of factors during manufacturing can alter the clinical performance of NiTi wires. The G4™ manufacturing processes some invented, some developed and others refined by G&H make G4™ NiTi distinct from all other NiTi archwires used in Orthodontics.

- Scientific Testing Protocols

Only scientific testing of a NiTi wire can determine its actual working characteristics. G4™ NiTi archwires undergo intense scientific testing during and after the manufacturing process: Each production lot of G4™ wire undergoes 14 separate quality tests during manufacturing. Every G4™ wire then undergoes a 28-point 100% final inspection before packaging. All G4™ wires successfully pass all testing so that performance characteristics can be guaranteed.

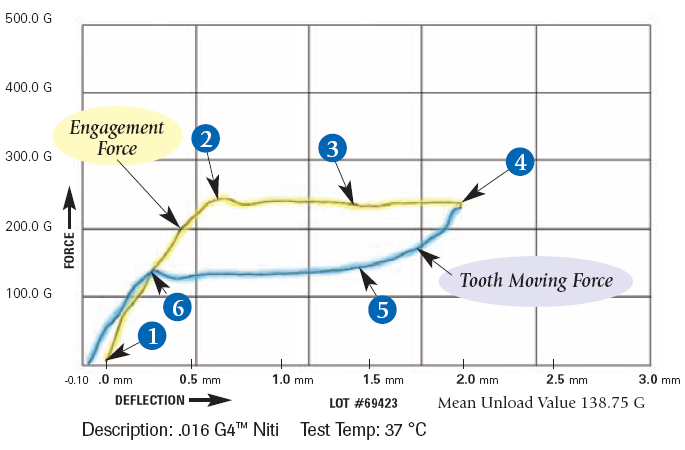

(Fig. A) G4™ Hysteresis Graph

(Fig. A) G4™ Hysteresis Graph Recovery Forces of G4™ Nickel Titanium

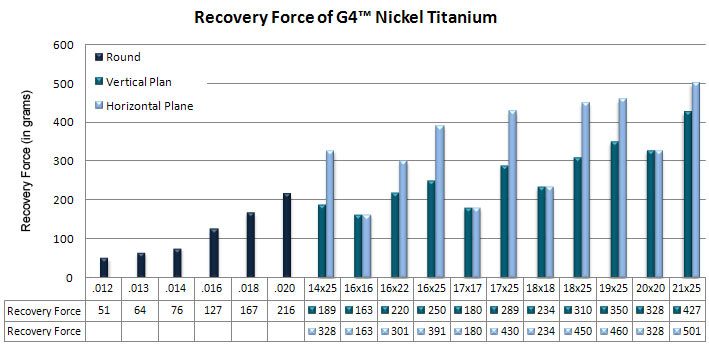

Recovery Forces of G4™ Nickel Titanium

The Clinical Significance of G4™ Nickel TitaniumThe clinically significant improvements to G4™ wire provide lower initial load forces and increased residual forces as full shape recovery progresses.

(Fig. A)

- Lower Load Forces of Engagement

Easier wire deflection and delivery to bracket, less stress on bonds and increased patient comfort.

- Higher Residual forces of recovery

Full shape recovery - complete unraveling and archform development by staying active to the end.